Eight benefits of using harmonic reducers in robot performance

Release time:

2022-10-11

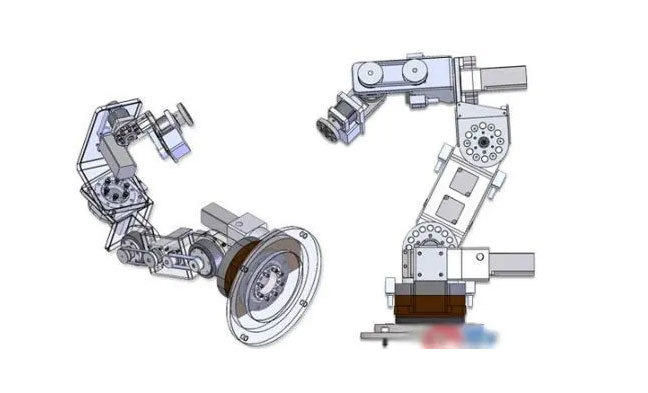

Harmonic gearbox: high performance, precision, lightweight, low noise, high efficiency, easy installation.

In robot performance, using harmonic gearboxs has the following eight advantages:

1.High reduction ratio: The single-stage coaxial structure can achieve a high reduction ratio of 1/50~1/160, providing powerful power support for the robot.

2.Small backlash: Compared with ordinary gear devices, harmonic drives have smaller backlash, bringing indispensable accuracy to the controller field.

3.High precision: Multiple teeth mesh at the same time, making the harmonic reducer characterized by high precision, and position and rotation accuracy are effectively guaranteed.

4.Simple installation: Because there are few parts and they are on the coaxial axis, the harmonic drive is easy to install and suitable for various scenarios.

5.Compact and lightweight: The volume is only 1/3 of the previous gear device and the weight is 1/2, achieving miniaturization and lightweight, but still having the same torque capacity and reduction ratio.

6.High torque capacity: Made of special steel with high fatigue strength, it can achieve high torque capacity and cope with various work needs.

7.High efficiency: The gear meshing and sliding are small, which reduces power loss, allowing the drive motor to be miniaturized while achieving a high reduction ratio.

8.Low noise: balanced operation, low noise and minimal vibration, providing a quiet and comfortable working environment.

The above eight advantages clearly demonstrate the important role of harmonic gearboxes in improving robot performance. Welcome to contact us for more details, we will wholeheartedly provide you with professional consulting services.

Key words:

Latest News

Share

WeChat Public Number

WeChat Consulting

Service Hotline

+86-0755-23714105

Tel: +86-13537655857 Mr. Xu

+86-13392402262 Wendy Luo

Email:XS@homwing.com Wendy@homwing.com

Add: 3/F, Building 1, Xinyuan Industrial Zone, Shangwei Park, Guxing Community, Xixiang Street, Bao'an District, 518126 Shenzhen,China